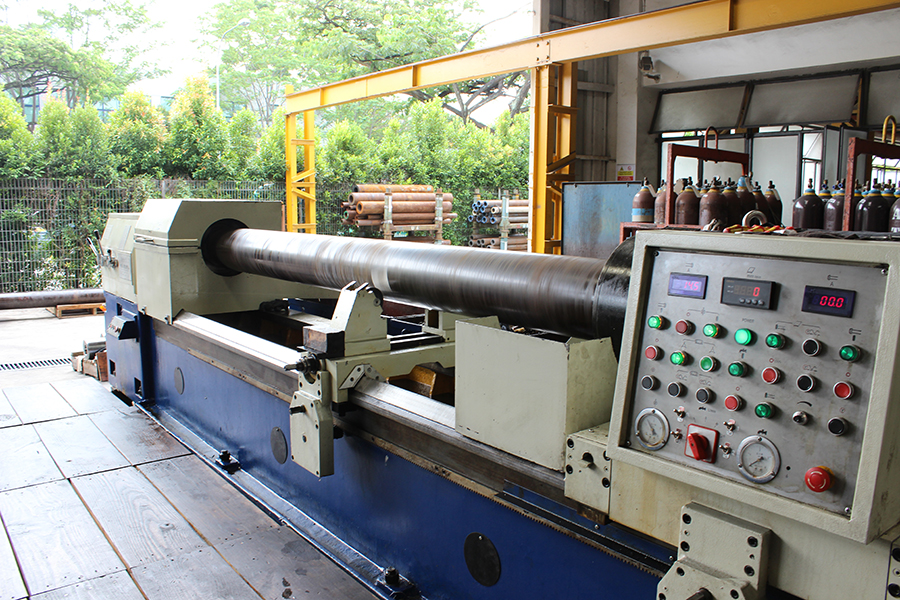

In the wide arena of machining endeavors, EPS prided itself to be the leading exponent in the machining field of deep-hole and long-shaft turning and boring for the oil & gas and marine industries. Our forte lies on our expertise in managing deep-hole length up to 20ft and inside diameter as large as 10 inches on a wide array of steel types, notably Inconel family in 925 and 718 series.

In our wide spectrum of machining capability and services offered, off-center drilling is our key signature specialty. We had met with great success in developing new machining methods and processes to produce off-center machining features with consistent reliability and speed.

In our wide array of machining services offered, EPS has long been recognized as a master craftsman in precision machining. We prided ourselves as a leading manufacturer in producing precision, highly complex and intricate steel components and accessories for the oil & gas, marine and aerospace industries through our extensive capability in multi-axis CNC turning, drilling, milling. Our forte lies on our expertise in managing products with inherently complex and intricate machining features of exceptional demand on tolerances and finishing.

Within our precision machining domain, we offer threading capability and services in API 5CT/5B connections, mechanical connections and Unified Thread Standards (UTS). We are equipped with comprehensive inventory of API thread gauges and metrological centers. We too possess with in-house sand-blasting and bead-blasting capability for thread surface treatment. Our sand-blasting and bead-blasting capability has gained endorsement for various global thread designers.

EPS has always specialized in its precision honing for achieving up to 32 RMS surface finished requirements. In order to achieve the highest quality precision honed parts, we believe in only the best, state-of-the-art machines, tooling and oil coupled with a team of highly skilled people with years of honing experience.