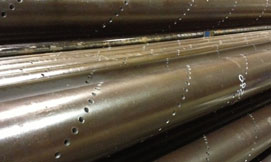

During the growing phase, EPS was first incorporated with two 27-spindles semi-CNC perforation line. To cater for the rising demand, in 2009, EPS expanded with a total of four perforation lines to support its existing customers. In 2010, EPS further proved its capabilities by converting its existing four perforation lines to vertical top down, fully CNC. In our continuous pursuit in manufacturing excellence, we again re-design and converted 2 existing vertical top down to now our signature 36-spindles fully CNC perforation line to improve on our productivity.

Our signature spindles were also originated from Japan which kicked in with a higher accuracy in terms of alignment during the entire perforation process regardless of material grades.With the flexibility and superior design in our perforation machines and equipment, we are capable of perforating a wide range of perforation designs regardless of complexity such as spiral or staggered patterns. We are able to humbly yield 1,200 joints per month, operating at two shifts. We pride ourselves in being capable of handling the most complex drilling patterns and configurations.We assure that we will give the best of quality in our drilling works, stringent quality controls and at all times demonstrating full satisfaction to our customers.

back to top